Top 3D Printer Programs for Impeccable Designs

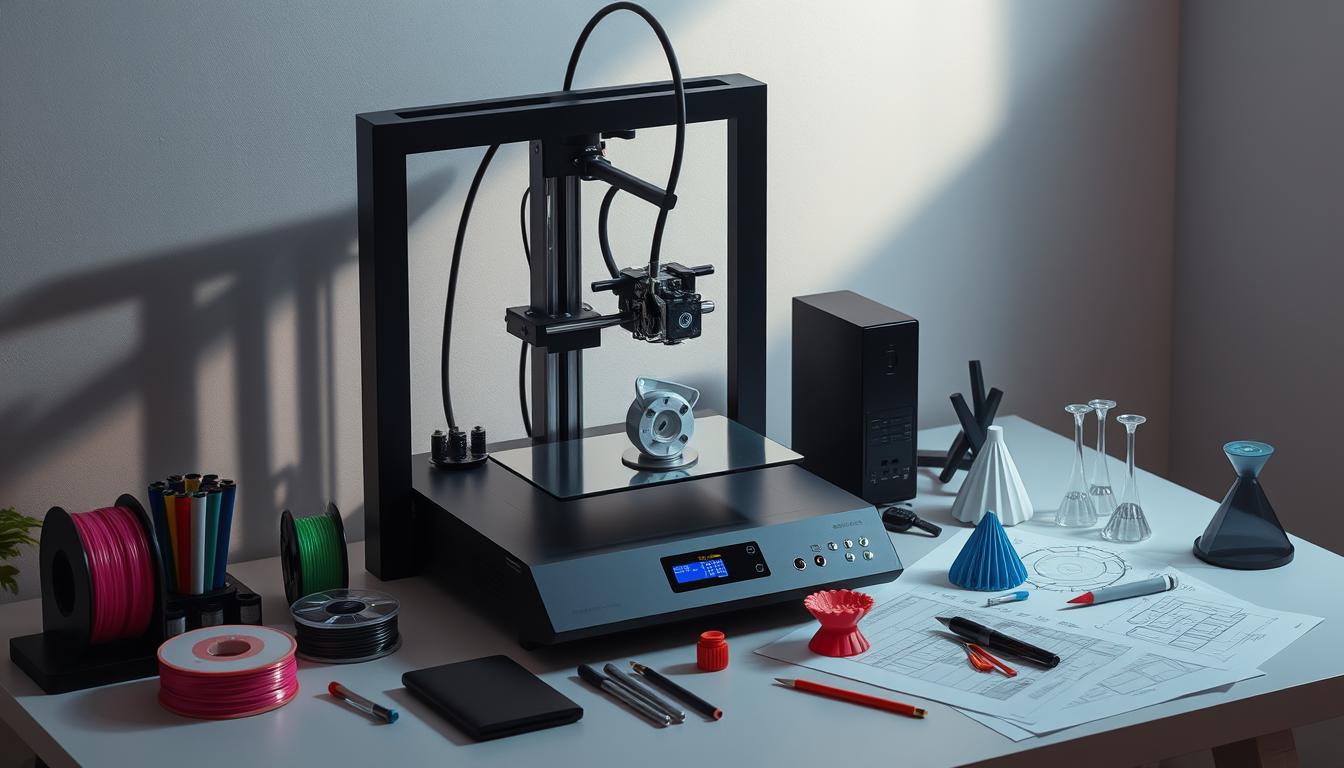

3D printer programs have changed how we turn digital ideas into real things. They are key for making detailed designs and improving the 3D printing process. Whether you need software for making prototypes or designing 3D models, the right choice is important.

As 3D printing grows in fields like education, healthcare, and cars, knowing about slicer software is vital. It makes printing easier and better. Let's explore the best 3D printing tools to make your designs perfect.

Key Takeaways

- 3D printer programs play a crucial role in turning digital designs into physical objects.

- Choosing the right slicer software can optimize print times and reduce material waste.

- Customization options enhance user control over print quality and performance.

- Advanced algorithms within these programs ensure accuracy and surface finish.

- 3D printing technologies are rapidly gaining popularity across various industries.

Understanding the Role of 3D Printer Programs in Design

3D printer programs are key in turning ideas into real things. They help designers add details and make changes. This software connects digital designs to real objects, making sure they are precise and high quality.

It makes 3D modeling easy, helping creators see their ideas clearly.

The digital printing process starts with setting up these programs. They create detailed plans for 3D printing. Good software boosts creativity and makes work flow better.

In fields like medicine and fashion, 3D printer programs are very important. They help make designs better and faster, saving money and improving results.

The 3D printing market is growing fast, expected to hit $41 billion by 2026. These programs are essential for new ideas, like custom hearing aids and 3D printed hip replacements. They show how advanced software changes the world.

Click to Watch Video Tutorial.

Types of 3D Printer Programs Available

The world of 3D printing software has many types of programs. Each one is made for different tasks in the 3D printing process. CAD software is at the heart, letting users make detailed designs and models.

Tools like AutoCAD, Fusion 360, and Blender show how CAD tools help designers. They offer a base for endless creativity.

Slicer software is another key part. Programs like Cura and PrusaSlicer turn CAD models into something 3D printers can use. They set things like layer height and infill density. There are seven programs that focus on this, making it easier to go from idea to real object.

Modeling software adds more to the mix, with special features for different industries. For example, nTop and Creo have advanced tools for engineers. They help with high-performance designs, showing the need for versatility in various fields like aerospace and industrial manufacturing.

The 3D printing software market has something for everyone. It lists 30 programs, with 13 open-source and 17 proprietary ones. Eight programs work on multiple operating systems, while others are for Windows, macOS, or Linux. This wide range means everyone, from beginners to experts, can find what they need.

For those looking to learn more, knowing about the different 3D printer programs is key. As technology grows, these programs will too. They will bring new tools and features to the 3D printing world.

Choosing the Right 3D Printer Program for Your Needs

Choosing the right software is key for good 3D printing results. Things like how easy it is to use, how complex the designs are, and what you need to print matter a lot. Beginners often choose Tinkercad because it's easy to use. It lets users start designing quickly, making learning fun.

More experienced users might prefer advanced programs like Fusion 360 or Solidworks. These offer detailed tools for professional projects. They help with complex designs and make work more efficient.

It's important to pair CAD tools with slicer software. This makes sure designs are ready for printing. Tools like Ultimaker Cura and PrusaSlicer make this easy. They adjust settings for better prints, reducing failures.

When picking 3D printer software, think about what you want to achieve. For more help on choosing 3D printer software, there are many resources out there.

3D Printer Programs: Slicer Software Explained

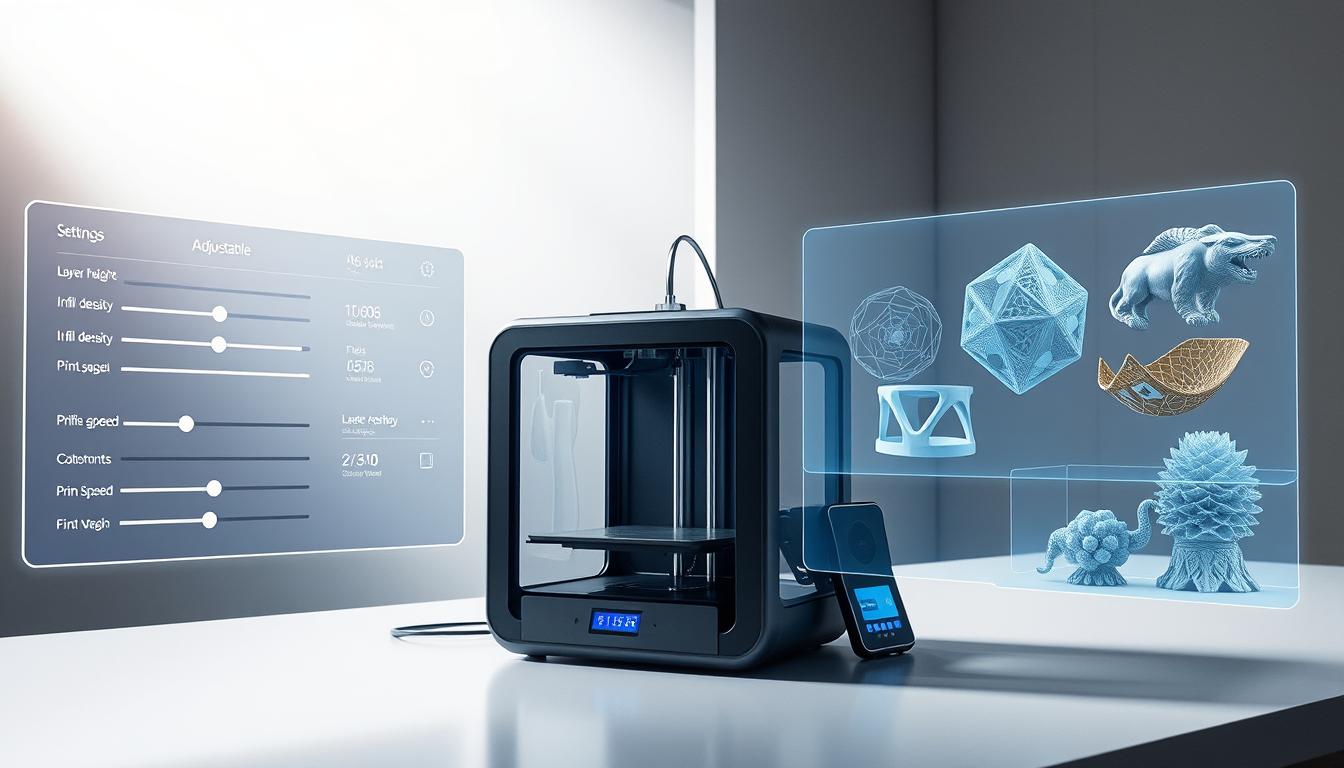

Slicer software is key in 3D printing. It turns complex CAD designs into commands 3D printers can follow. Knowing how slicer software works is vital for those starting with 3D printing. It affects both the quality and speed of prints.

The Importance of Slicer Software

Slicer software is very important. It changes 3D models into G-code for printers to use. It handles file types like .STL, .3MF, and .OBJ. This way, printers get all the details they need for printing.

Programs like Cura and PrusaSlicer show how slicers make prints faster and better. They use resources wisely without losing quality.

How Slicer Software Translates Models

Slicer software breaks down 3D models into layers. This makes the printing process simpler. Users can see prints in 2D and 3D, making complex designs more accurate.

Advanced slicers let users tweak settings and add supports. They can even adjust layer heights. These features help get the best results for each project.

Top Features to Look for in 3D Printer Programs

Finding the right features in 3D printer programs can really boost your 3D printing. Look for these key features when choosing software:

- User Interface: A simple interface makes it easy for everyone to use the software.

- Customization Options: Being able to customize designs is crucial for meeting project needs.

- Advanced Algorithms: These algorithms help make prints look better and be more accurate.

- Compatibility: The best software works with many printers, giving you more options.

- File Format Support: Being able to use different file types makes the design-to-print process smoother.

Knowing about these features helps you pick software that fits your needs and goals.

| Feature | Description | Importance |

|---|---|---|

| User Interface | Easy navigation for effective operation | Enhanced user experience, even for beginners |

| Customization Options | Tailored designs for specific project needs | Offers creative freedom |

| Advanced Algorithms | Improves accuracy in print quality | Makes sure models are precise |

| Compatibility | Works with many printer types | Increases use across different technologies |

| File Format Support | Handles multiple file types well | Makes the design-to-print process easier |

Knowing about 3D printing software capabilities can greatly improve your projects. This is even more true as more affordable and versatile printers become available.

Exploring Popular 3D Printer Programs

3D printer programs are key for designers and engineers. Software like Blender, Tinkercad, and Autodesk Fusion 360 meet different needs. Knowing these options helps pick the right software for each user.

Overview of Leading Software Solutions

Blender is a versatile open-source tool for many design tasks. It's loved by artists and hobbyists. Tinkercad is simple and web-based, great for beginners and schools.

Autodesk Fusion 360 has advanced features and gets high praise for its capabilities. Siemens NX is for advanced industrial use, with tools for metal printing. Solid Edge is professional-grade but easy to use, perfect for small to medium businesses.

Pricing and Accessibility of 3D Printer Programs

Software cost is a big factor in choosing. Tinkercad and Ultimaker Cura are free, perfect for those watching their budget. Onshape costs $1,500 per user per year, and SOLIDWORKS is $2,820 annually, for professionals.

Autodesk Fusion is $680 per user per year, offering good value. Siemens NX's monthly cost of about $614.25 might be too high for small businesses.

How easy software is to use affects its popularity. Many professional tools are powerful but hard for beginners. Autodesk Fusion, for example, has a steep learning curve. Onshape, with its real-time collaboration, is easier to use and great for teamwork.

Benefits of Using Advanced 3D Printer Programs

Advanced 3D printer programs offer many benefits. They make design work better and faster. This helps in many fields.

These programs help make designs more precise. They can create shapes that old ways can't. This is a big plus.

They also save a lot of material. Unlike old ways, 3D printing only uses what's needed. This is good for the planet and saves money.

It's a win-win for businesses and the environment. It makes things cheaper and helps the planet.

These programs make making prototypes quick. Old methods took days or weeks. But 3D printing can do it in hours.

This is great for fast-moving fields like cars and planes. It helps them stay ahead.

It also means less stuff to store. This saves space and money.

In healthcare, 3D printing is even more important. It can make custom parts and even organs. This can save lives.

It's also changing how we learn. Schools are using it to teach kids. It helps them think and solve problems better.

| Benefits | Details |

|---|---|

| Reduced Material Waste | Uses only what's needed, saving money and the planet. |

| Faster Prototyping | Makes parts in hours, speeding up work. |

| Customizable Designs | Can make complex shapes and custom parts. |

| Improved Cost Efficiency | Saves on storage and materials, making things cheaper. |

| Enhanced Learning Opportunities | Helps with STEM and boosts creativity in students. |

Integrating 3D Printer Programs with Your Workflow

Adding software to your workflow is key for better 3D printing. Tools like 3DPrinterOS connect different brands like Bambu Lab and Ultimaker. This helps schools with many 3D printers work better together.

Optimizing 3D printing means having one control panel for all printers. This makes managing easier and saves staff time. It also lets more people join in 3D printing workshops, making learning fun.

In makerspaces, using 3D print queue software is crucial. It helps use printers well, so projects are done on time. Schools can watch prints online and fix problems fast, saving time.

Using cloud-based 3D printing solutions is smart. It keeps files safe and makes workflow better. Automation helps keep things running smoothly, with less downtime.

| Benefit | Description |

|---|---|

| Centralized Control | Manage multiple printers with a single interface, reducing complexity. |

| Increased Participation | Streamlined workflows encourage more users to engage in 3D printing activities. |

| Maximized Capacity | Queue management software optimizes the use of available printing resources. |

| Remote Monitoring | Address printing issues promptly, leading to increased productivity. |

| Cloud Solutions | Reduce risks associated with physical media and improve storage efficiency. |

Adding 3D printing software makes things run smoother. Going for automation and cloud solutions boosts efficiency. This lets teams focus on creativity, not workflow problems.

Maximizing Design Efficiency through 3D Printer Programs

Getting the most out of 3D printing is key. Using top-notch 3D printer programs makes designing better. They offer cloud access, so you can work from anywhere. This helps both solo designers and big teams work smoothly.

Good software boosts your work speed and cuts down on mistakes. It makes creating things easier and more efficient.

Tips for Effortless Design Modifications

Changing designs doesn't have to be hard. Here are some tips for easy adjustments:

- Use advanced slicing tools for different printers. This lets you set up the best settings for your prints.

- Choose cloud-based options for quick file access. This speeds up your work.

- Use live monitoring to watch your prints. This helps spot and fix problems fast.

- Try Hyper FFF tech for faster prints without losing quality. This saves time on design changes.

Collaborative Tools within 3D Printer Software

Collaborative tools are vital for better teamwork. They help students and teachers work together in schools. They also make it easier for companies to work together, improving how things get done.

By customizing software, companies can fit it to their needs. For more on making design work better, see this article: maximize the potential of your 3D printer.

Post-Processing: Enhancing Your Designs After Printing

Post-processing is key in 3D printing. It makes the final product look and work better. There are 16 ways to do this, but CNC machining is most used. It can get very precise, which is great for many industries.

Chemical dipping is one way to make 3D prints look better. It uses strong chemicals that need care. The size of the container limits how big the prints can be. Spray coating is also used, making it fast for big jobs.

Sanding is good for making prints smooth, like those from SLA. Sandpaper with high grits can make them shiny. Even though SLA prints have fewer lines, sanding can still be needed.

Improving 3D prints often means using more than one method. For example, UV-cured fillers need special chambers. Powder coating adds a protective layer, making parts last longer.

Here's a detailed overview of various post-processing techniques alongside their characteristics:

| Technique | Advantages | Considerations |

|---|---|---|

| CNC Machining | High accuracy and precision | Time-consuming and requires expertise |

| Chemical Dipping | Smooths surfaces effectively | Requires careful handling of caustic materials |

| Sanding | Creates high-quality finishes | Labor-intensive, varying results based on grit |

| Powder Coating | Durable and resistant to chipping | Limitations in color and texture options |

| UV Curing | Reduces weak points in parts | Requires UV chamber and specific exposure times |

Investing in post-processing can really boost the value of your products. It turns prototypes into products ready for the market. Good post-processing meets standards and makes products last longer and look better.

Conclusion

We looked at how picking the right 3D printer programs is key. It makes design work better and more fun. These programs have cool features like great slicing tools and easy-to-use interfaces.

They help with everything from school projects to big business needs. This makes 3D printing better for everyone.

We also talked about how to use 3D printer programs with design software. This makes work easier and saves time. As we move towards 2025, 3D printing will get even better.

It will be more about working together, being efficient, and precise. This is good for creativity and for businesses too.

If you're starting with 3D printing, look into these programs. They help bring your ideas to life. This is great for schools and businesses alike.

FAQ

What are the benefits of using 3D printer programs?

3D printer programs offer many benefits. They improve design and precision. They also save time and reduce waste.

Users can customize prints closely to their needs. This leads to better results in creative projects.

How do I choose the right 3D printer program for my needs?

When picking a 3D printer program, think about a few things. Look at user experience and design complexity. Also, consider your specific printing needs.

Beginners might want easy-to-use software. Experienced users might need advanced features and customization options.

What is the role of slicer software in 3D printing?

Slicer software is key in 3D printing. It turns digital 3D models into formats that printers can read. Programs like Cura and PrusaSlicer help make prints faster and use less material.

They let users tweak settings for better quality. This ensures prints come out well.

What key features should I look for in 3D printer programs?

Look for an easy-to-use interface and customization options. Also, check for advanced algorithms for precision. Make sure it works with your printer and supports different file formats.

Understanding these features can make your 3D printing better.

Can you recommend some popular 3D printer programs?

Some top 3D printer programs are Blender, Tinkercad, and Fusion 360. Each has its own special features. They meet different needs and offer various prices.

How can I maximize my design efficiency with 3D printer programs?

To boost design efficiency, use quick modification tips. Also, explore team tools in the software. These help make design work smoother and faster.

What are the essential post-processing techniques I should know?

Important post-processing techniques include sanding, bead blasting, and vapor smoothing. These methods help get smooth surfaces and detailed prints.

They make your 3D prints look and work better.

Advancing 3D generation to new heights

moving at the speed of creativity, achieving the depths of imagination.